Press seals

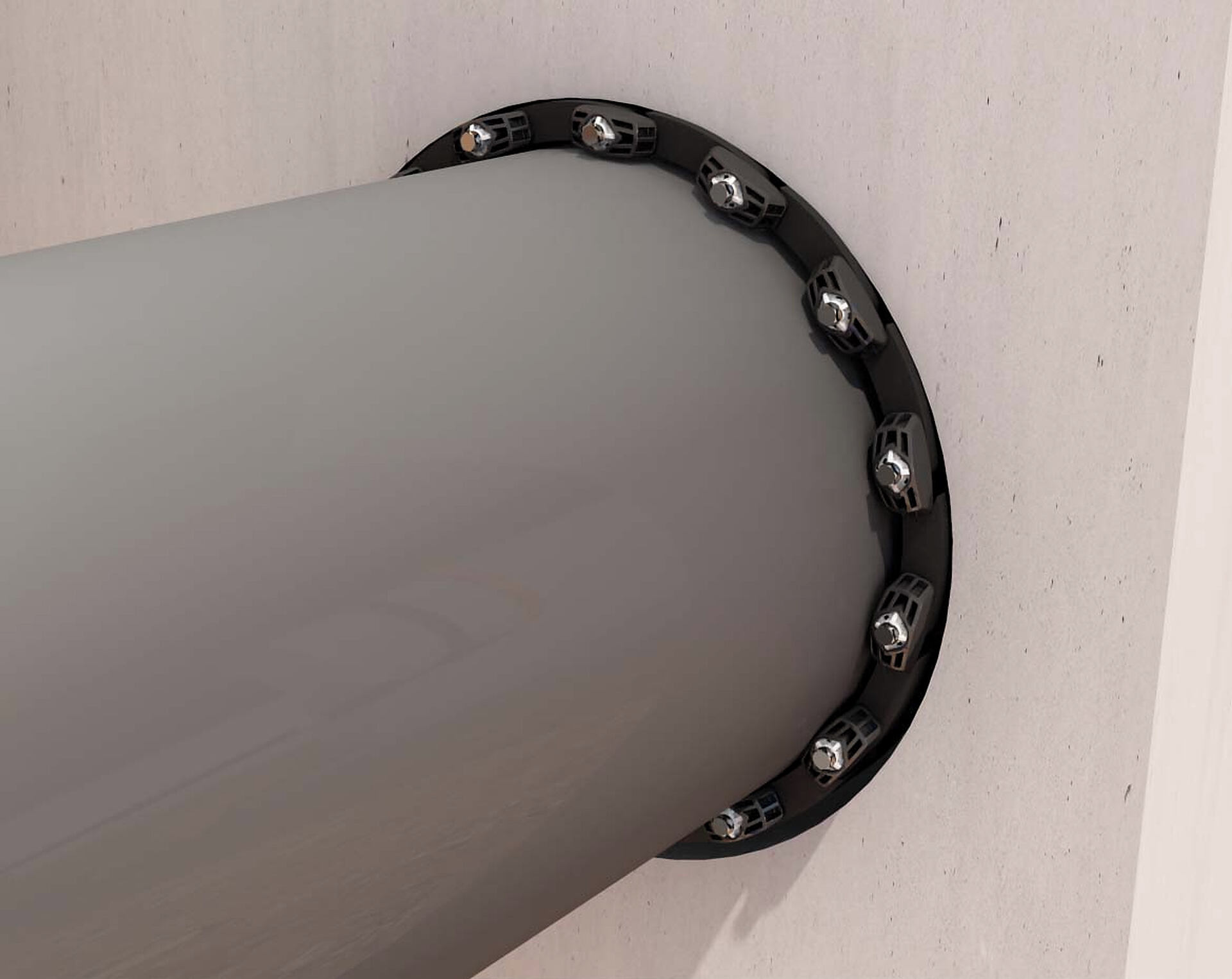

The innovative press seals from Hauff-Technik provide you with every possible opportunity for reliable sealing of core drills or wall sleeves for one or a number of pipes.

These range from closed seal inserts for first-time installation to split seal inserts for retrofit sealing of pipes that have already been laid. We can provide the ideal press seal for every requirement and task, be it tailor-made to the millimetre or suitable for universal use on site, centric or eccentric. Quick and cost-effective.

Standard

Standard press seal

with continuously variable super segment ring technology

HSD SSG

Standard press seal

with stepped variable super segmented ring technology

HSD SSG

Modular seal

Modular pipe seal

GKD

Standard press seal

for building connections

HSD100 EW 1x24-44+4x7-12 b40 A2/EPDM

Standard press seal

HSD100 RW 1x25/32/40+3x6-18 b40 A2/EPDM

Standard press seal

sealing width 20 mm

HSD b20

Standard press seal

sealing width 40 mm

HSD b40

Standard press seal

sealing width 80 mm

HSD b80

Standard press seal

with powder coating

HSD C b40

Sealing set

for corrugated cable ducts and pipes

WRD

Standard press seal for internal sealing of corrugated pipes

with segmented ring technology

WIN SG b40 A2/EPDMCustom

Rubber Compression Seals as a Flexible System for Building Connections

In the process of establishing house connections, variations in the diameter of supply lines versus the entry point into the building are common. Hauff-Technik addresses this challenge with innovative rubber compression seals, designed to create a seamless and secure barrier. These seals guarantee that house entries remain fully gas- and watertight, protecting your building from potential leaks. With a comprehensive selection of products, Hauff-Technik ensures that you have the right solution for every application, whether through rubber compression seals or other compatible systems.

Functionality and Properties of Rubber Compression Seals

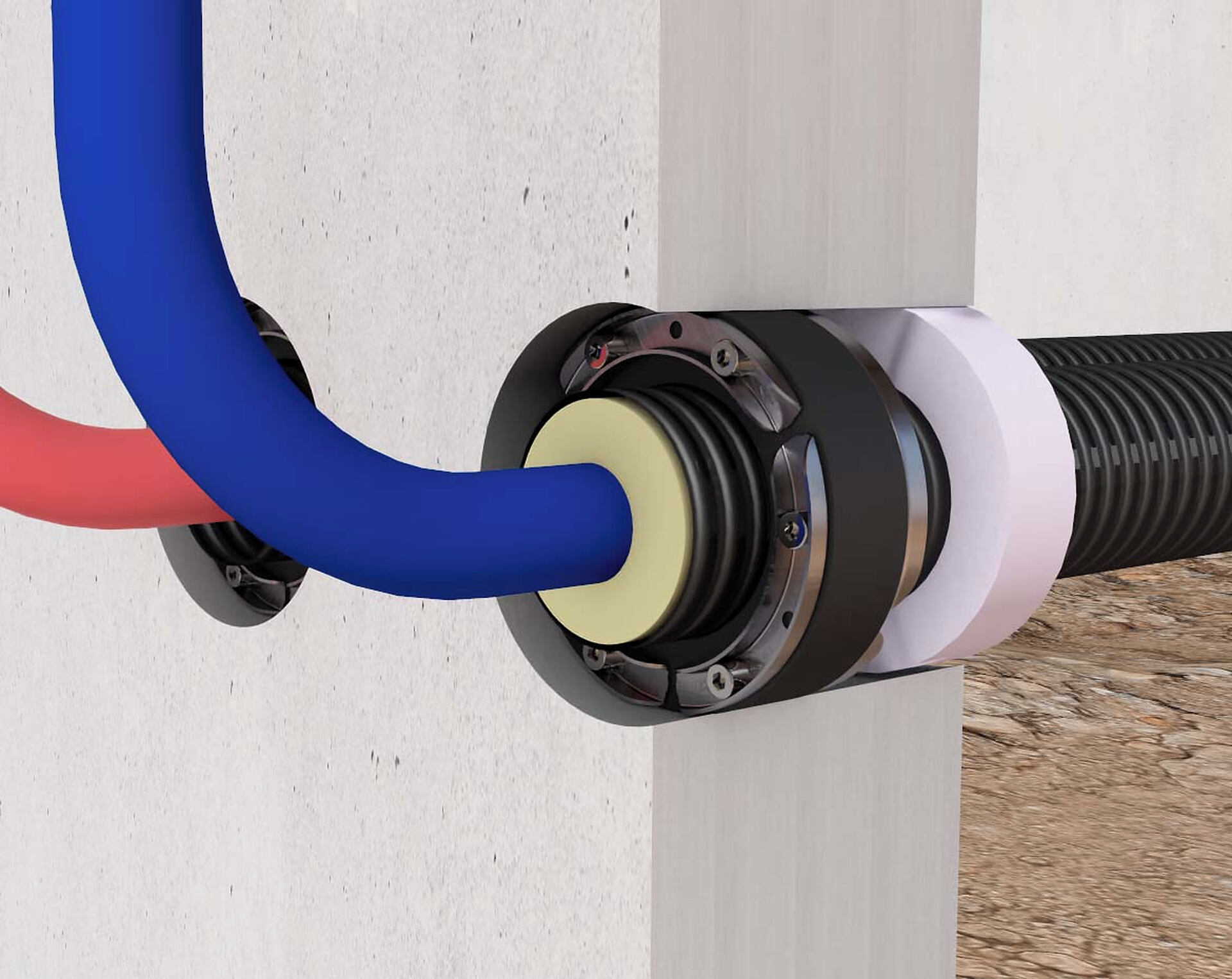

A rubber compression seal is a sealing element that directly contacts the supply line at the entry point of the cable penetration. This seal is integrated into the press seal or another suitable system for the cable penetration.

The sealing elements are made of EPDM rubber (ethylene propylene diene monomer rubber), which provides high resistance to external influences. With proper installation, the seal is gas and water-tight at pressures of up to 2 bar or more. Additionally, EPDM rubber is temperature-resistant within a range of -40 to +140 degrees Celsius.

Core drills and liner pipes with diameters of 100 to 300 mm are compatible with such seals. Customized sealing systems can also be manufactured for pipes with diameters starting from 40 mm.

Applications of Rubber Compression Seals

Rubber compression seals can be utilized for both newly installed pipes and existing ones, regardless of whether they are located in core drillings or liner pipes. Hauff-Technik offers standard press seals in various widths, covering a range from 20 to 80 mm, depending on the system and diameter.

For press seals equipped with step-less super-segment ring technology, selecting the appropriate diameter for the supply line is straightforward. Each segment of the seal has a precise diameter label. Before the line is inserted, any excess layers must be removed until the desired diameter is achieved.

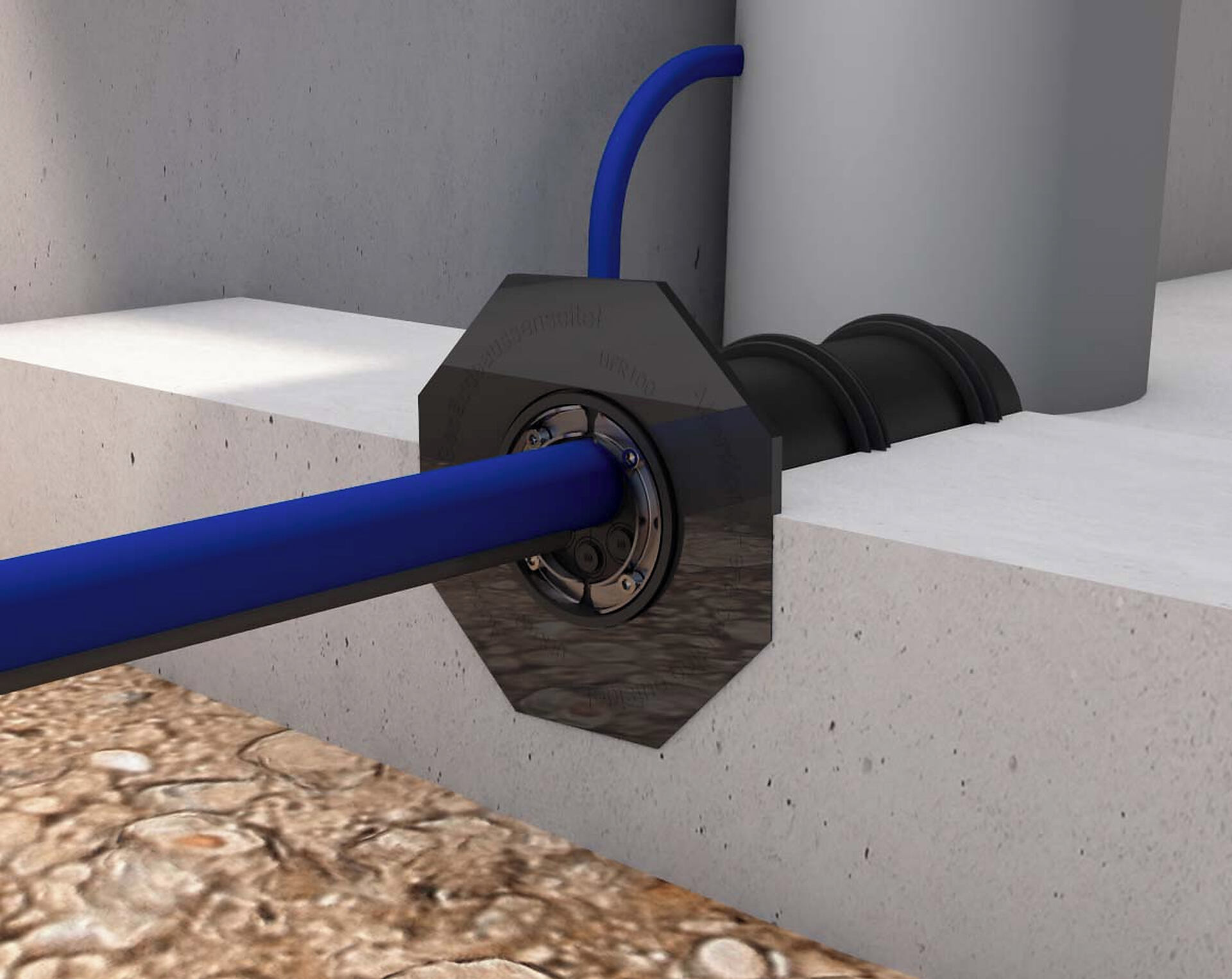

For larger supply lines, a modular chain seal can be employed, enabling its use as a KG pipe seal as well. The modular design allows the chain seal to accommodate various diameters of pipes and boreholes. This type of rubber compression seal ensures home entries that are gas and water-tight up to 5.0 bar.

Additionally, one major advantage is that the installation can be completed within five minutes. When used as a KG pipe seal, the chain seal is first positioned around the drain pipe. It is then inserted into the core drilling of the building. Finally, the rubber seal is tightened using a ratchet. A color-coded assembly check indicates whether the installation has been performed correctly and confirms that the connection point is sealed.

Suitable Press Seals for Specific Pipe Systems

When working with various pipe systems and supply lines, specialized rubber compression seals are often necessary. Hauff-Technik offers an extensive range of sealing systems specifically designed for galvanized pipes and stainless steel liner pipes, ensuring optimal performance and reliability.

Hauff-Technik also provides standard press seals designed for rainwater utilization systems. These high-quality rubber compression seals come pre-equipped with the necessary entries for various lines, allowing for all connections to be easily implemented through a single core drilling with a diameter of 100 mm. This feature simplifies installation and enhances system efficiency.

In addition, Hauff-Technik offers advanced sealing systems with flanges specifically designed for storage tanks. These flanges are ideal for facilities that store, fill, or handle hazardous materials like transformer oils or diesel fuels, such as JGS facilities or biogas plants.

The rubber compression seals from Hauff-Technik also incorporate silicone, which ensures compliance with stringent regulations concerning the handling of water-polluting substances. Each sealing flange features a width of 15 mm, providing a secure and effective seal that meets industry standards.

Help us improve our website service.

Where would you place yourself?

Architect & designer

Wholesaler

Telecoms

Utility company

Installer

Construction company

Please choose your region

-

Belgium

Belgium

-

Česko

Česko

-

Danmark

Danmark

-

Deutschland

Deutschland

-

España

España

-

France

France

-

Global

Global

-

Hrvatska

Hrvatska

-

Italia

Italia

-

Luxembourg

Luxembourg

-

Magyarország

Magyarország

-

Nederland

Nederland

-

Österreich

Österreich

-

Polska

Polska

-

Schweiz

Schweiz

-

Slovenija

Slovenija

-

Slovensko

Slovensko

-

Sverige

Sverige

-

United Kingdom

United Kingdom

-

Global

Global

-

USA

USA

-

Global

Global

-

India

India

-

中国

中国

-

Global

Global

-

الإمارات العربية المتحدة

الإمارات العربية المتحدة