Wall sleeves

As an expert in sealing products, we know that a leakproof building entry starts with getting the "hole in the wall" right first time. It is for this reason that we have dedicated several decades to the development of innovative, high-quality and easy-to-use wall sleeves and flange constructions.

We can supply products for installation flush with shuttering, for setting in mortar and for retrofit dowel-fixing. Fixed/loose flange constructions provide a reliable means of integrating bitumen thick coatings or waterproof sheeting, the use of which is prescribed according to DIN 18195 Part 6 for protection against water penetration from the outside or seepage water.

Inserts and flanges / new construction

Universal wall sleeve

for any type of wall

UFR

Universal wall sleeve

for any type of wall

UFR B

Cement-coated wall sleeve

with special coating

ZVR

Fibre cement wall sleeve

FZR

Fibre cement wall sleeve

split

FZRG

Connection wall sleeve

AFR 100

Connection wall sleeve

for installation in double walls/element walls

AFRE 100

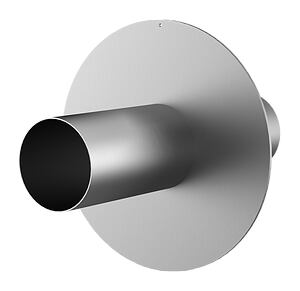

Stainless steel wall sleeve with puddle flange

for setting in concrete

FUM A2

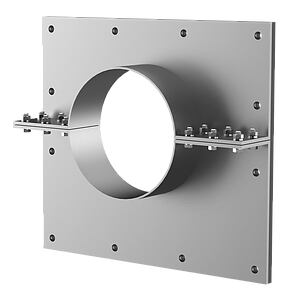

Fixed/loose flange wall sleeve made from stainless steel

for setting in concrete according to DIN 18531*

FLFE DIN18531 A2

Fixed/loose flange wall sleeve made from stainless steel

for setting in concrete for black tank according to DIN 18533

FLFE DIN18533 A2

Fixed/loose flange wall sleeve galvanised

For setting in concrete and connecting bituminous coating

FLFE DIN18533 St-A3CInserts and flanges / subsequent installation

Renovation wall sleeve

SFR

Stainless steel flange

for retrofit installation

FA A2

Stainless steel flange split

for retrofit installation

FAG A2

Fixed/loose flange wall sleeve made from stainless steel

for retrofit dowelling, according to DIN 18531*

FLFA DIN18531 A2

Fixed/loose flange wall sleeve made from stainless steel

for retrofit dowelling for black tank according to DIN 18533

FLFA DIN18533 A2

Fixed/loose flange wall sleeve galvanised

for retrofit dowelling for black tank

FLFA DIN18533 A3CCasing Pipes for New Constructions and Retrofitting

The key to effective building entries lies in the use of high-quality casing pipes. Reliable and robust pipe entries are vital for ensuring durable and completely sealed connections for various utilities, including electrical and telecommunications cables, water lines, and more. Hauff-Technik provides the right casing pipes designed for both new construction projects and retrofitting applications. Opt for Hauff-Technik to guarantee that your building connections are not only secure but also compliant with the latest industry standards, enhancing the overall integrity and longevity of your building's utility systems.

Solutions from Hauff-Technik for Pipe Penetrations

Selecting the right products is essential for effective planning and execution of pipe entries during the rough construction phase. Hauff-Technik provides a wide variety of casing pipes, ensuring that you always have the right solution for your specific needs.

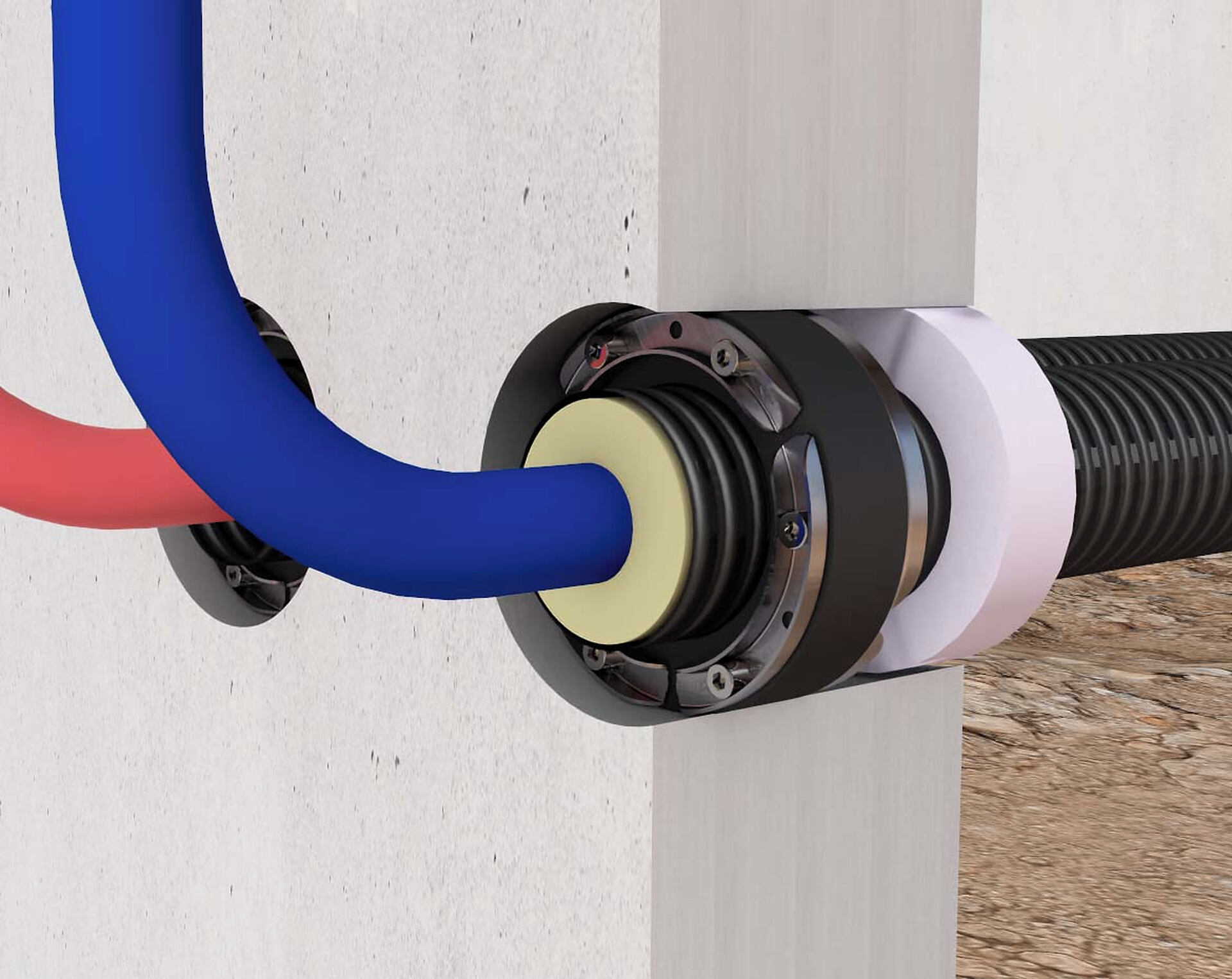

For example, fibre cement casing pipes are versatile and suitable for all wall types. Their distinctive ribbed outer surface allows for a highly effective seal when installed, enhancing moisture resistance.

In contrast, cement composite pipes with a specialized coating are specifically engineered for water-tight reinforced concrete structures, commonly referred to as "white tanks." This coating forms a seamless bond with the concrete post-installation, ensuring durability and integrity.

Lightweight universal casing pipes made from PVC-U are ideal for all types of walls, including those constructed with modular systems. These PVC pipes can also be combined with thick bitumen coatings due to the integrated working flange, providing added flexibility.

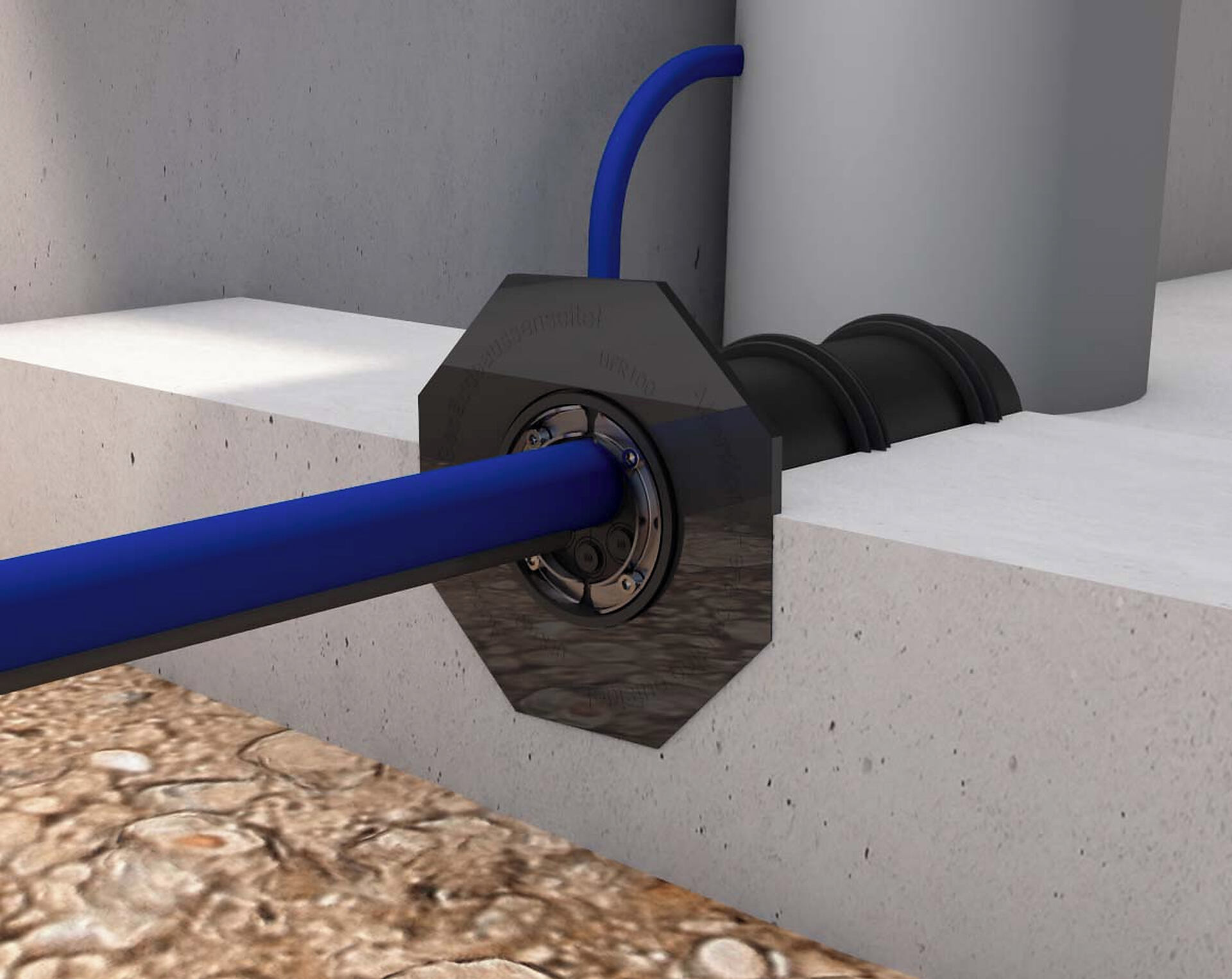

For enhanced functionality, pipes equipped with cable funnels are ready for immediate media conduction. They feature cable protection tubes and a central flange that serves as an effective water barrier, ensuring that installations remain watertight.

Cement composite pipes, like all other pipe entries from Hauff-Technik, can be easily customized on-site to the desired length. The casing pipes are available in various pre-manufactured lengths, ranging from 70 to 1,200 mm, allowing for versatile application in different construction scenarios.

Casing Pipes for the Later Installation and Sealing of Pipe Penetrations

Sometimes, utility lines are laid through temporary openings that may be poorly sealed or fail to meet the necessary standards for gas and water tightness. In some instances, there might not be any sealing at all, leading to an urgent need for a reliable solution. Additionally, when renovating old and possibly leaking penetrations, repair pipes become essential.

Hauff-Technik addresses this need by offering various types of repair casing pipes that can be seamlessly integrated with existing media lines. For example, split fibre cement casing pipes can be inserted into the existing opening individually, allowing both halves to be securely embedded in concrete or mortar.

For new wall penetrations, one-piece repair casing pipes provide an excellent alternative. These pipes are resistant to breakage and can also be easily installed and embedded at a later stage.

To ensure that the interior of the repair casing pipe—housing the utility lines—is sealed against gas and water ingress, you can make use of either a ring space seal or a chain link seal from Hauff-Technik. This ensures that your installations remain safe and compliant with all necessary standards.

Loose Flanges and Wall Sleeves for Combination with Casing Pipes or Core Drills

Hauff-Technik provides a comprehensive range of flanges and sleeves tailored to enhance the functionality of various pipe penetrations. These components play a crucial role in ensuring effective sealing solutions.

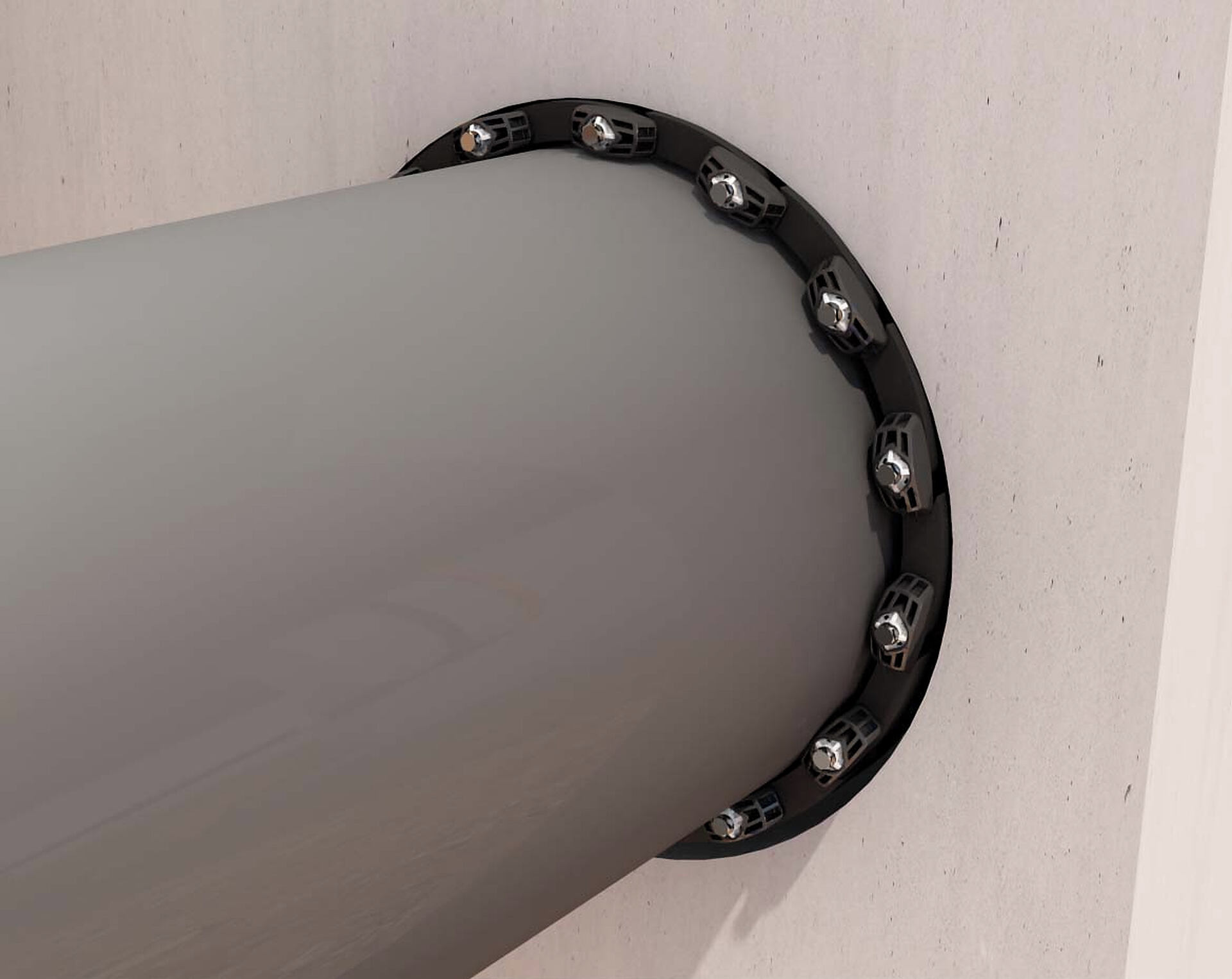

Wall sleeves are designed for use with pipes made from diverse materials, including steel, copper, cast iron, or plastic. Typically crafted from fibre cement or PVC, these sleeves work in conjunction with appropriate ring space seals to provide hydrostatic sealing for penetrations. Depending on their construction, they offer features such as corrosion resistance, non-combustibility, and the ability to maintain pressure and water-tight seals, while being non-conductive as well.

Using fixed and loose flanges allows for the creation of connection interfaces for pipelines, making them easy to disassemble without being permanently bonded. Available in stainless steel or galvanized steel, these flanges can be embedded securely in concrete or attached as loose flanges. They are compatible with core drills, pipes, and standard wall penetrations, and come in sizes ranging from 80 to 500 mm, tailored to fit the diameter of the casing pipe. Custom options can also be obtained from Hauff-Technik, making these flanges ideal for establishing gas and water-tight pipe penetrations.

Help us improve our website service.

Where would you place yourself?

Architect & designer

Wholesaler

Telecoms

Utility company

Installer

Construction company

Please choose your region

-

Belgium

Belgium

-

Česko

Česko

-

Danmark

Danmark

-

Deutschland

Deutschland

-

España

España

-

France

France

-

Global

Global

-

Hrvatska

Hrvatska

-

Italia

Italia

-

Luxembourg

Luxembourg

-

Magyarország

Magyarország

-

Nederland

Nederland

-

Österreich

Österreich

-

Polska

Polska

-

Schweiz

Schweiz

-

Slovenija

Slovenija

-

Slovensko

Slovensko

-

Sverige

Sverige

-

United Kingdom

United Kingdom

-

Global

Global

-

USA

USA

-

Global

Global

-

India

India

-

中国

中国

-

Global

Global

-

الإمارات العربية المتحدة

الإمارات العربية المتحدة