Cable entry system HSI150/HSI90

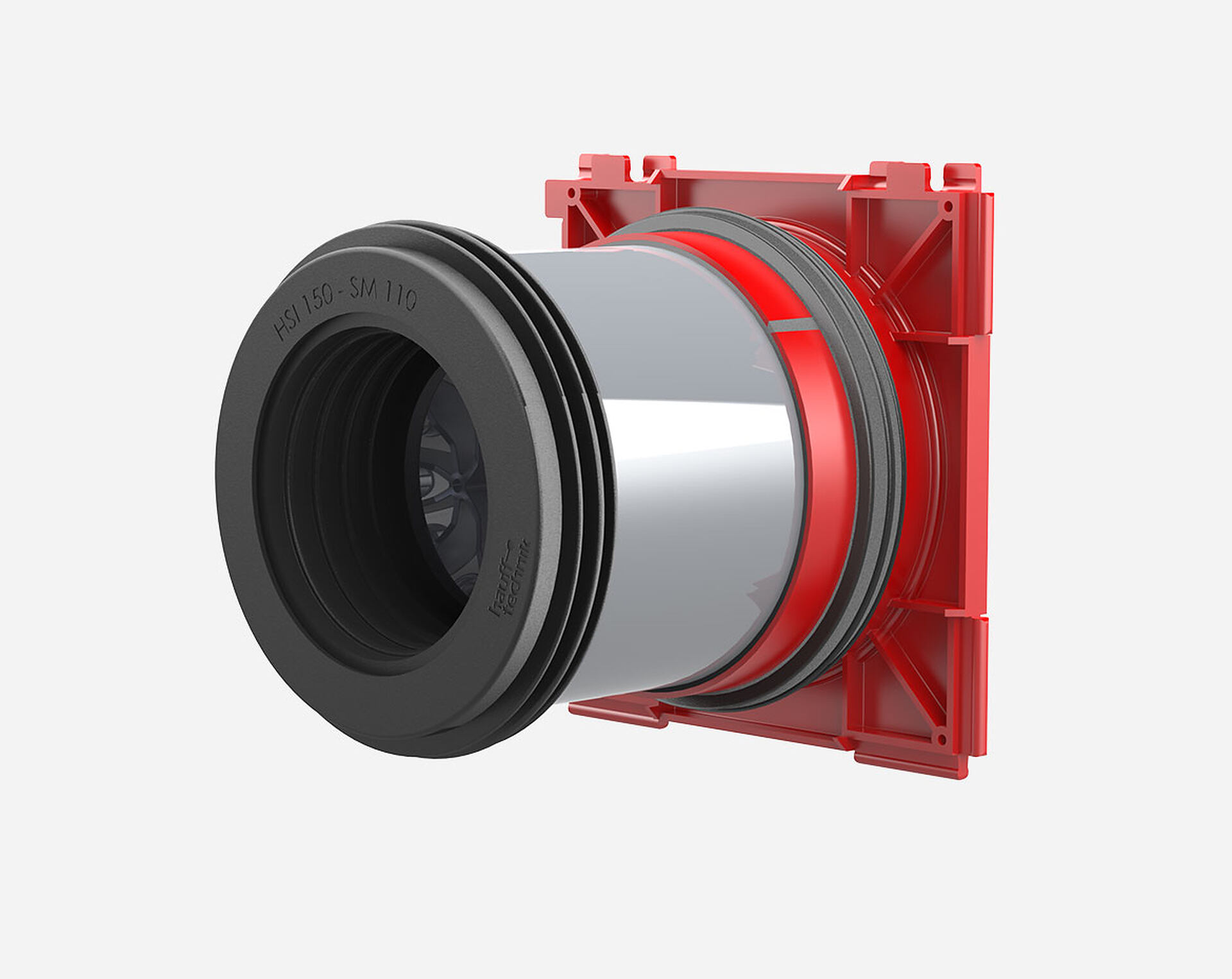

The HSI cable entry system impresses thanks to its modular design.

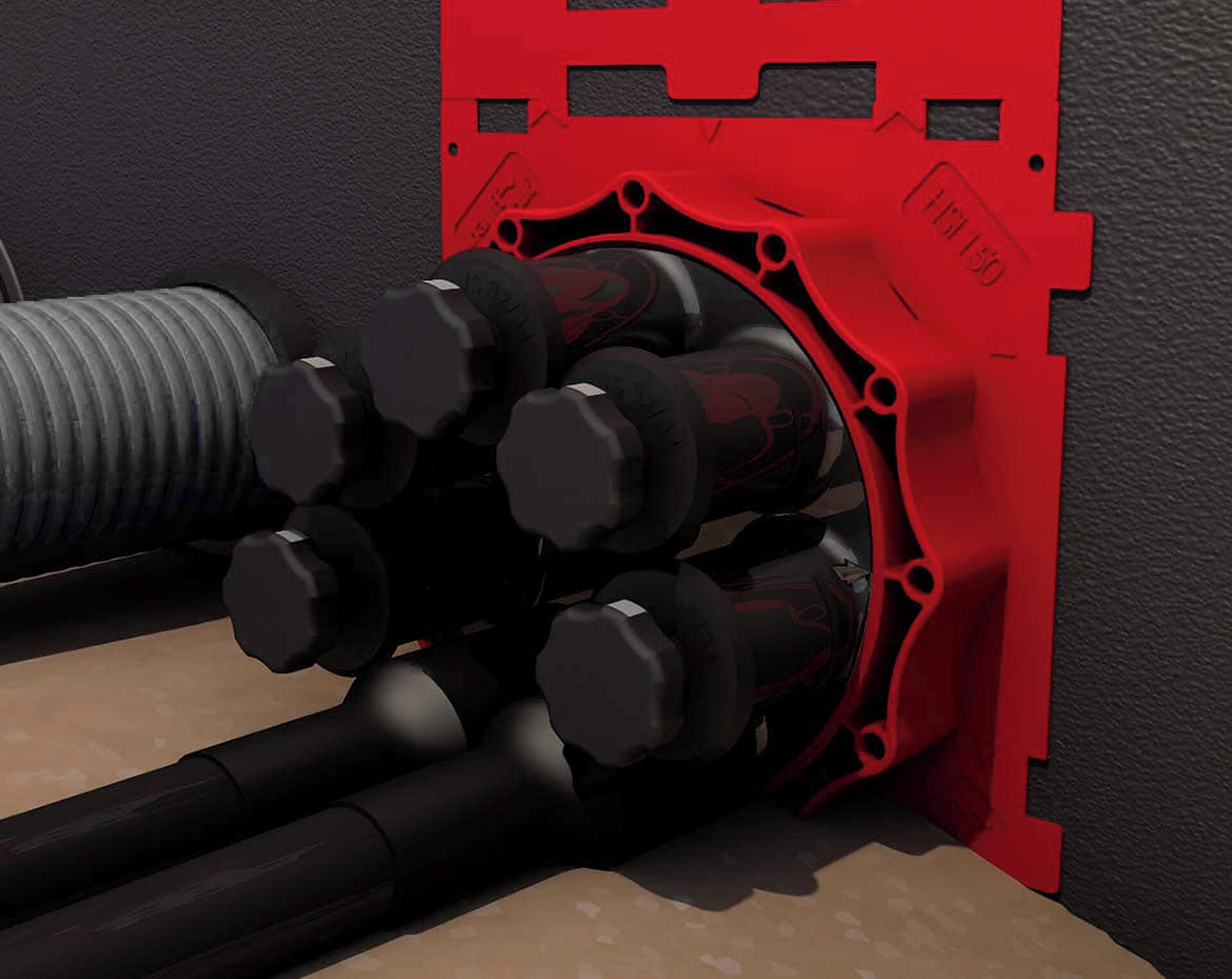

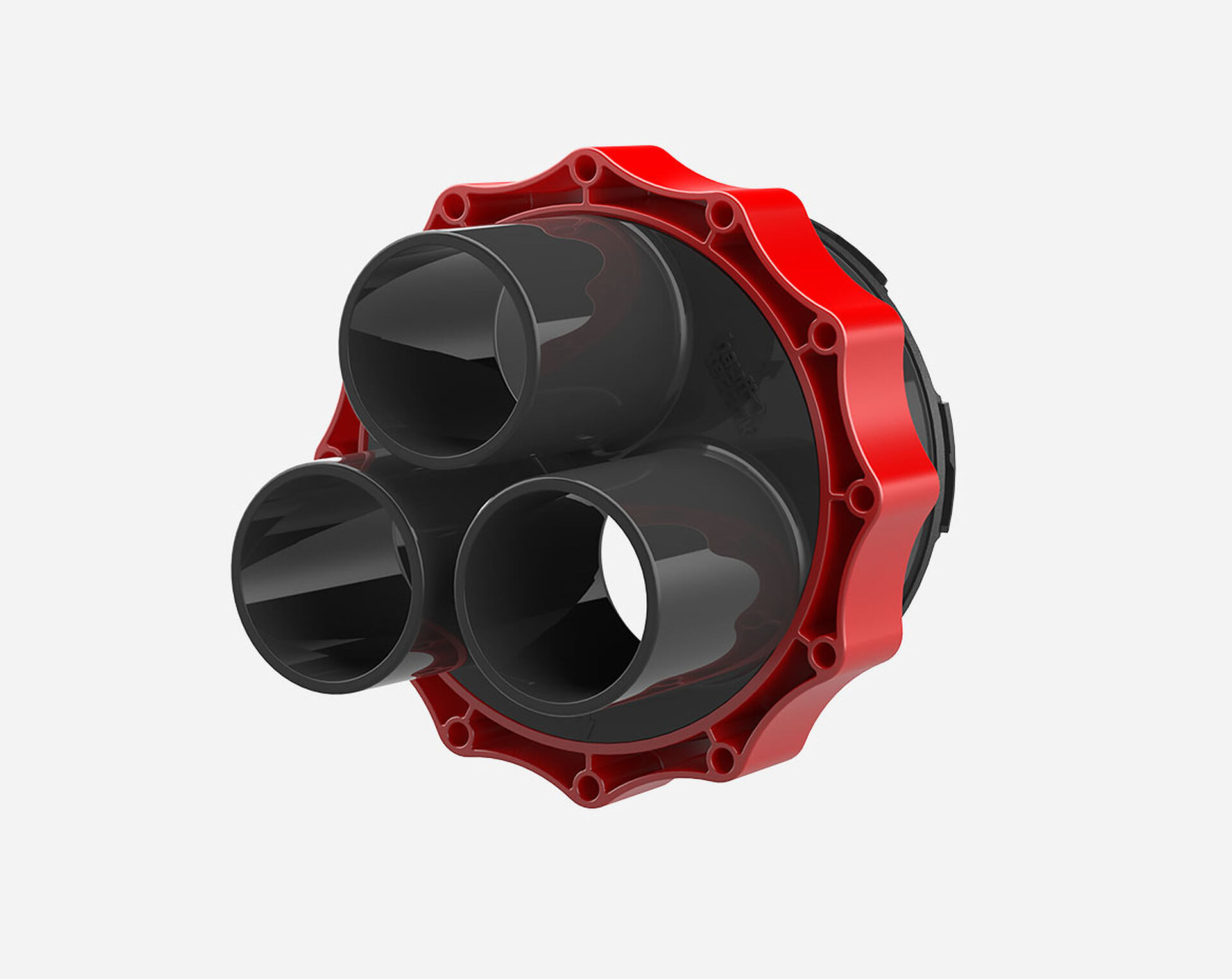

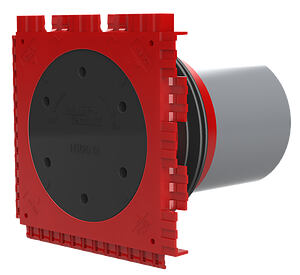

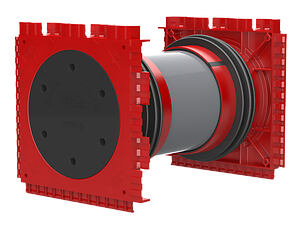

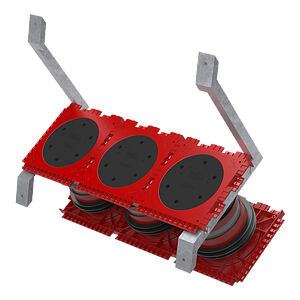

The system is available in two sizes with a nominal diameter of 150 or 90 mm and sets the standard for cable entries for installations flush with the formwork in concrete walls. Here, the wall insert HSI150/HSI90 offers maximum flexibility during subsequent use and is fitted with a pressure-tight closing cover ex works. A variety of system seals are available for sealing cables – in closed or split versions, depending on the requirements – and for pressure-tight empty duct connections.

Hauff-Technik also offers the KES150/KES90 pressure-tight cable entry system, which is compatible with the HSI150/HSI90 system and features a Hateflex spiral hose as well as various options for cable sealing. This system can relied upon to provide optimum protection for the cables that are being laid.

Inserts

One-sided connection option

External duct connection

HSI150

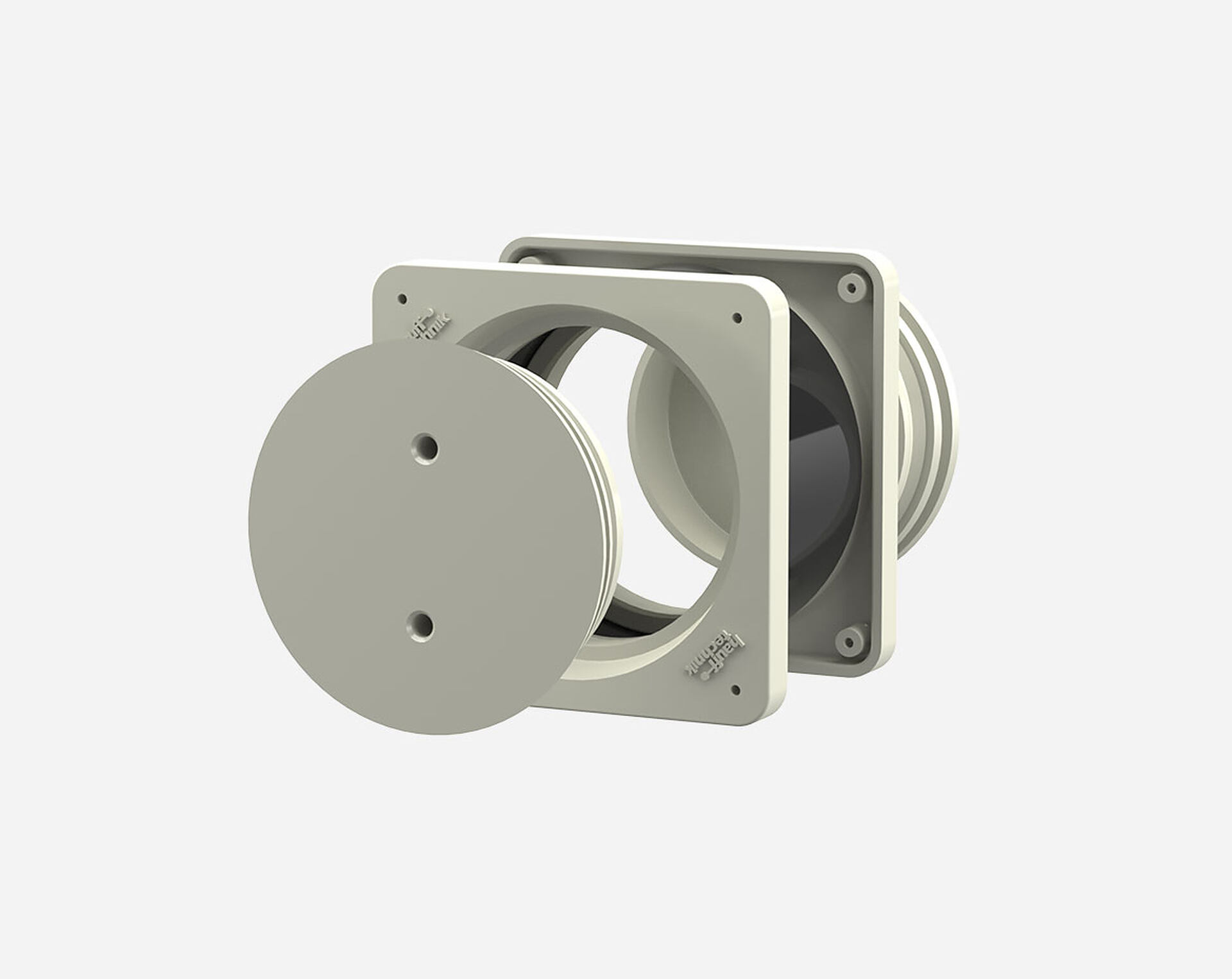

Single wall insert with foldable rubber sleeve

for setting in concrete and connecting cable ducts

HSI150 KMA

Single wall insert with plug-in socket

for setting in concrete and connecting smooth cable ducts

HSI150 GSM

Single wall insert with plug-in socket

adjustable length, for setting in concrete and connecting smooth cable ducts

HSI150 GSM VariaHSI90

Connections possible on both sides

HSI150

Double wall insert

for setting in concrete

HSI150 K2/X

Double wall insert

adjustable length, for setting in concrete

HSI150 K2 Varia

Double slanted wall insert

for setting in concrete

HSI150 1xZ K2 S_°/X

Double wall insert with flange connection

for setting in concrete

HSI150 1xZ K2 AF/X

Double wall insert

for setting in concrete, for black tank with fixed/loose flange

HSI150 FLFE/X DIN18533 W2-EHSI90

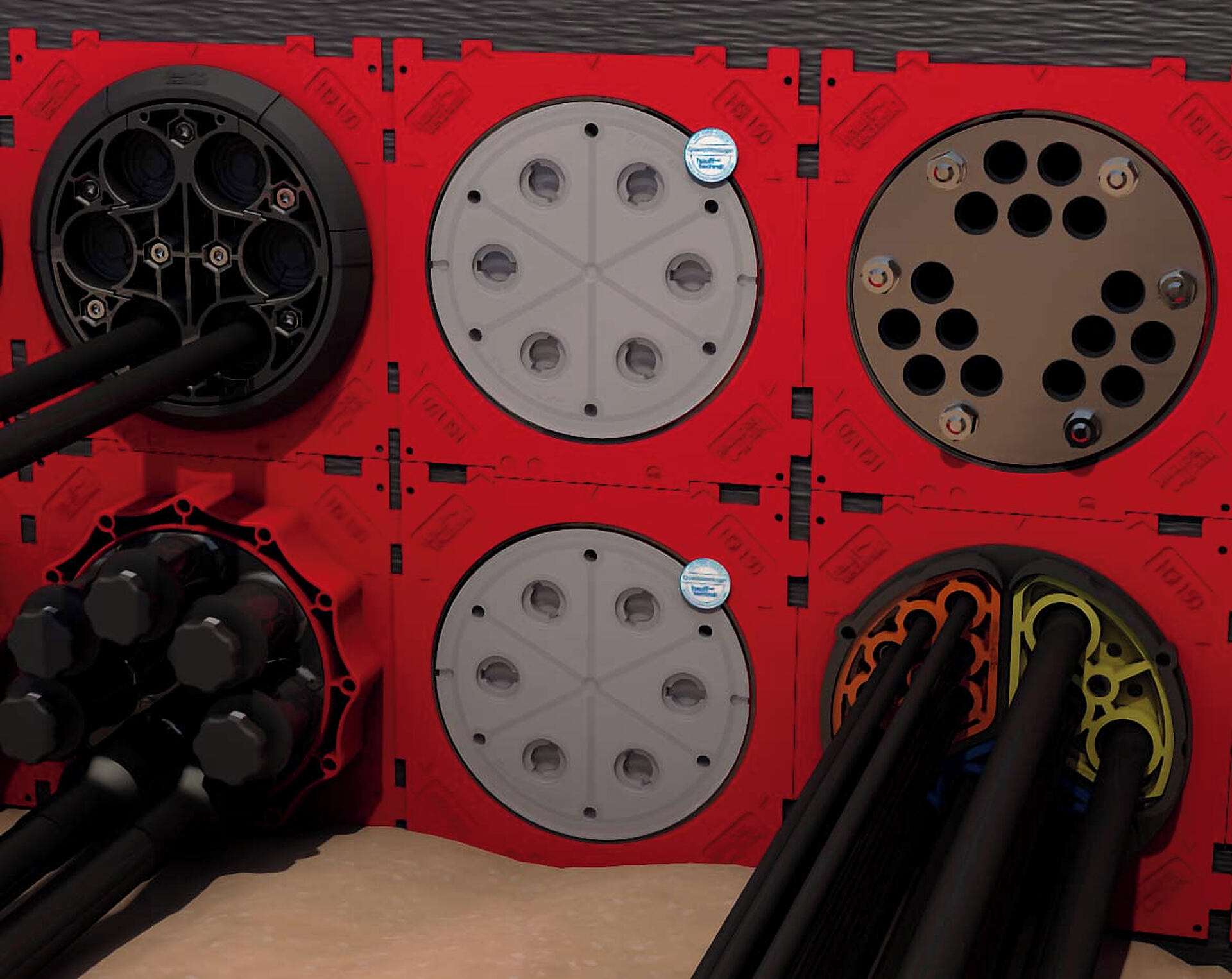

System inserts

Cable seals

HSI150

System cover

Cable sealing with elastomer shrink technology

HSI150 SF3x58

System cover

Cable seal with heat shrink technology

HSI150 D WS

System cover

Cable seal with cold shrink technology

HSI150 D KS

Closing cover

for empty wall inserts and polymer flanges

HSI150 DT

Split system cover

for retrofit sealing

HSI150 DG

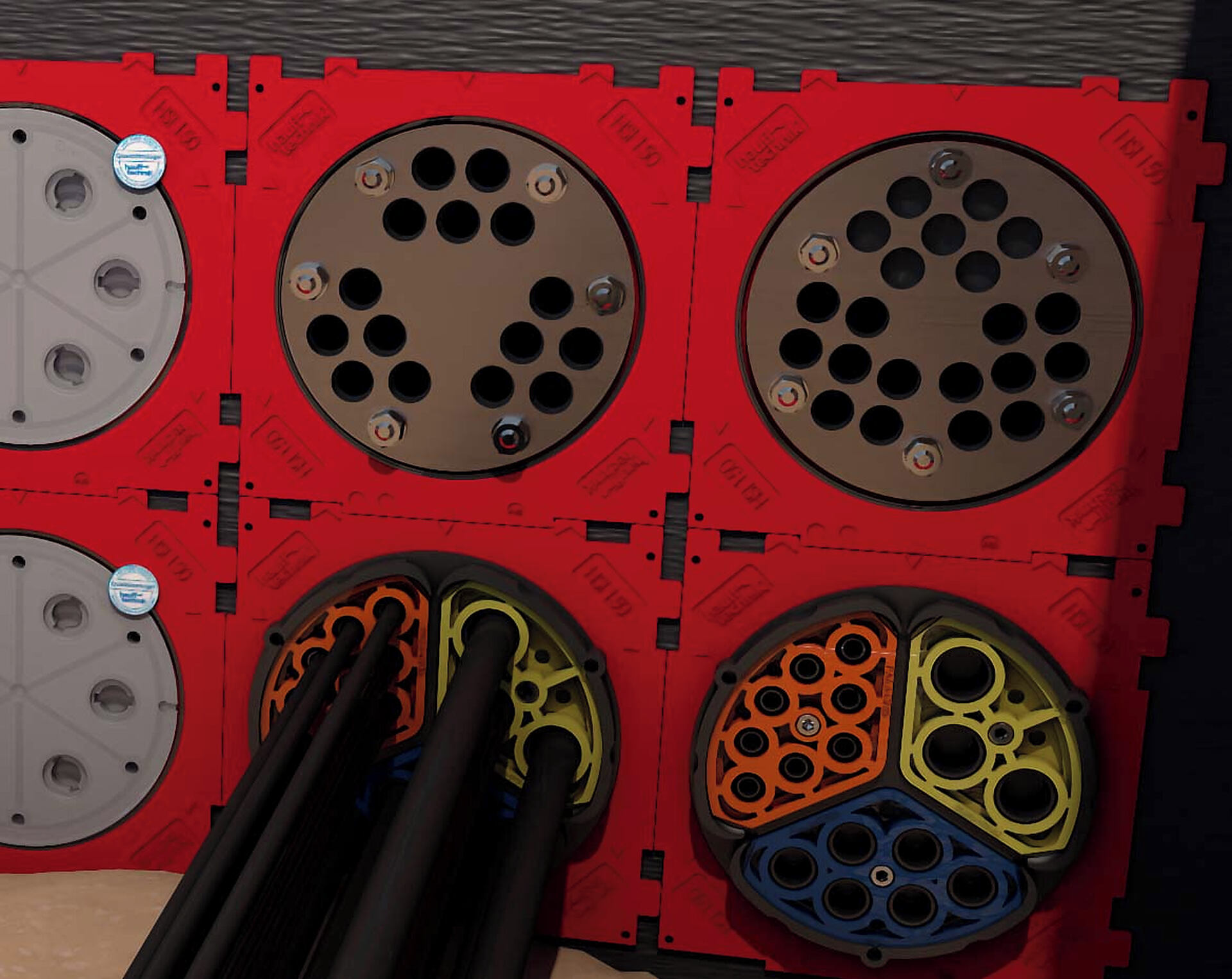

SEGMENTO

system cover for holding segments

HSI150 S3

SEGMENTO

Segments for installation in HSI150 S3 system cover

SEG

Customized press seal

with segmented ring technology

HRD150/160 SGi b60

Customized press seal

for micro pipes and empty conduits

HRD150 b60 A2/EPDMHSI90

Cable duct connections

HSI150

System cover

with sleeve method for plastic spiral duct

KES MA150 D

System cover

with sleeve method for smooth cable ducts

HSI150 MA GR

System cover

with sleeve method for corrugated cable ducts

HSI150 MA WR

System cover

with cold shrink-fit method for corrugated cable ducts

HSI150 D KS WR

System cover

with plug-in socket for smooth cable ducts

HSI150 D GSMHSI90

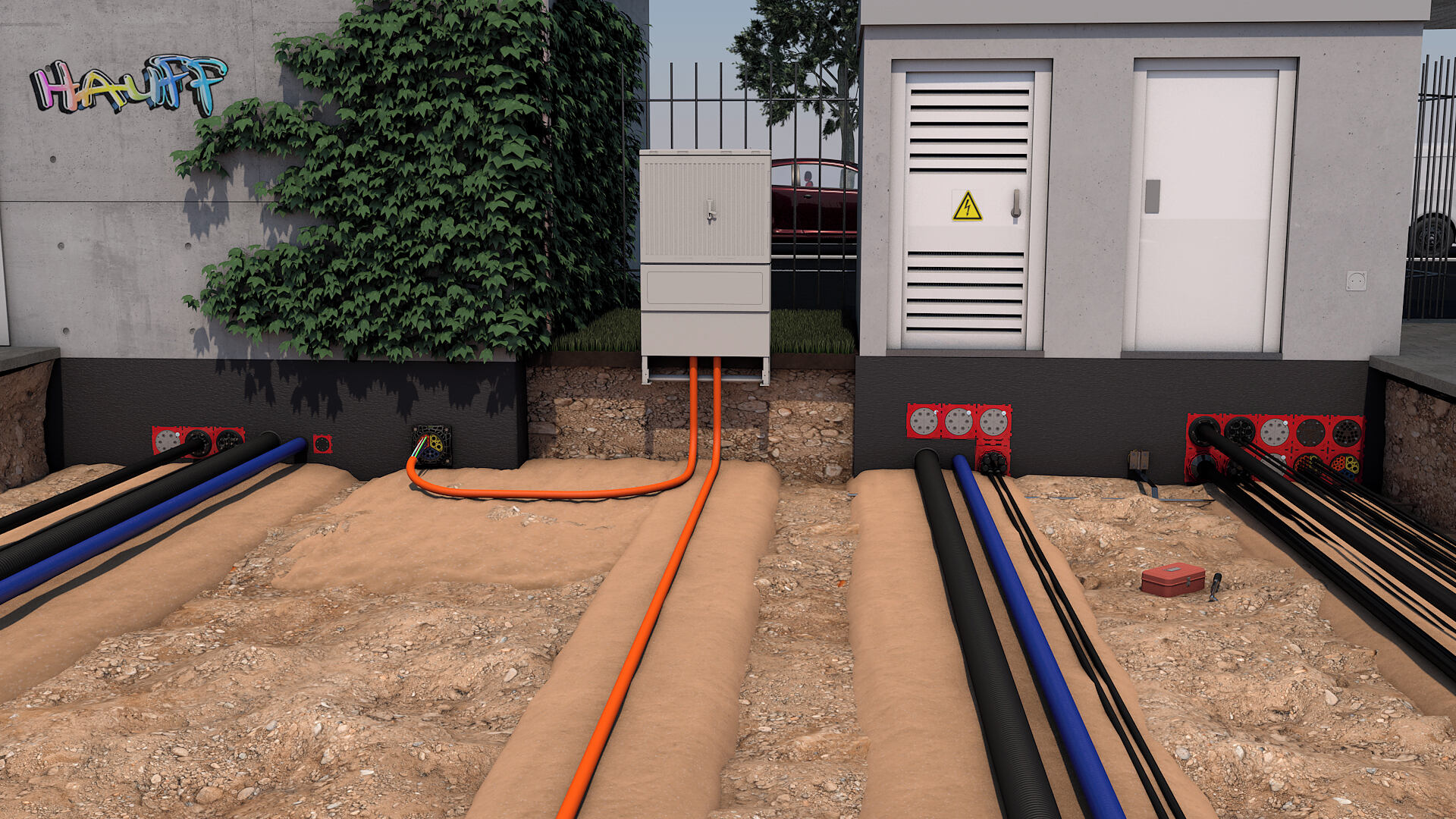

Cable Entries with 150 mm Diameter – Flexibility with Cable Protection Sleeves

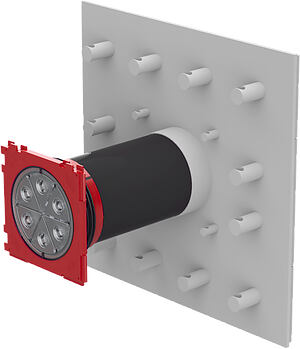

Building entry points are vital for bringing utility lines into a building. It’s important to consider future-proofing during the construction process. Installing a cable protection sleeve provides an efficient solution for long-term planning. Over time, replacing utility lines or adding new ones becomes a regular task for any building.

Using a cable protection sleeve offers greater flexibility for construction projects. The 150 mm diameter cable entry can be embedded in concrete during the build. This size accommodates multiple utility lines, each with its own sleeve, making it easier to add new cables later without major modifications.

Water- and Gas-Tight Installation for Maximum Security

House entries can break vapor and moisture barriers, posing a risk. Hauff-Technik’s cable entry system provides builders and property owners with a secure solution, ensuring full protection from gas and moisture infiltration for both the entry and individual utility lines.

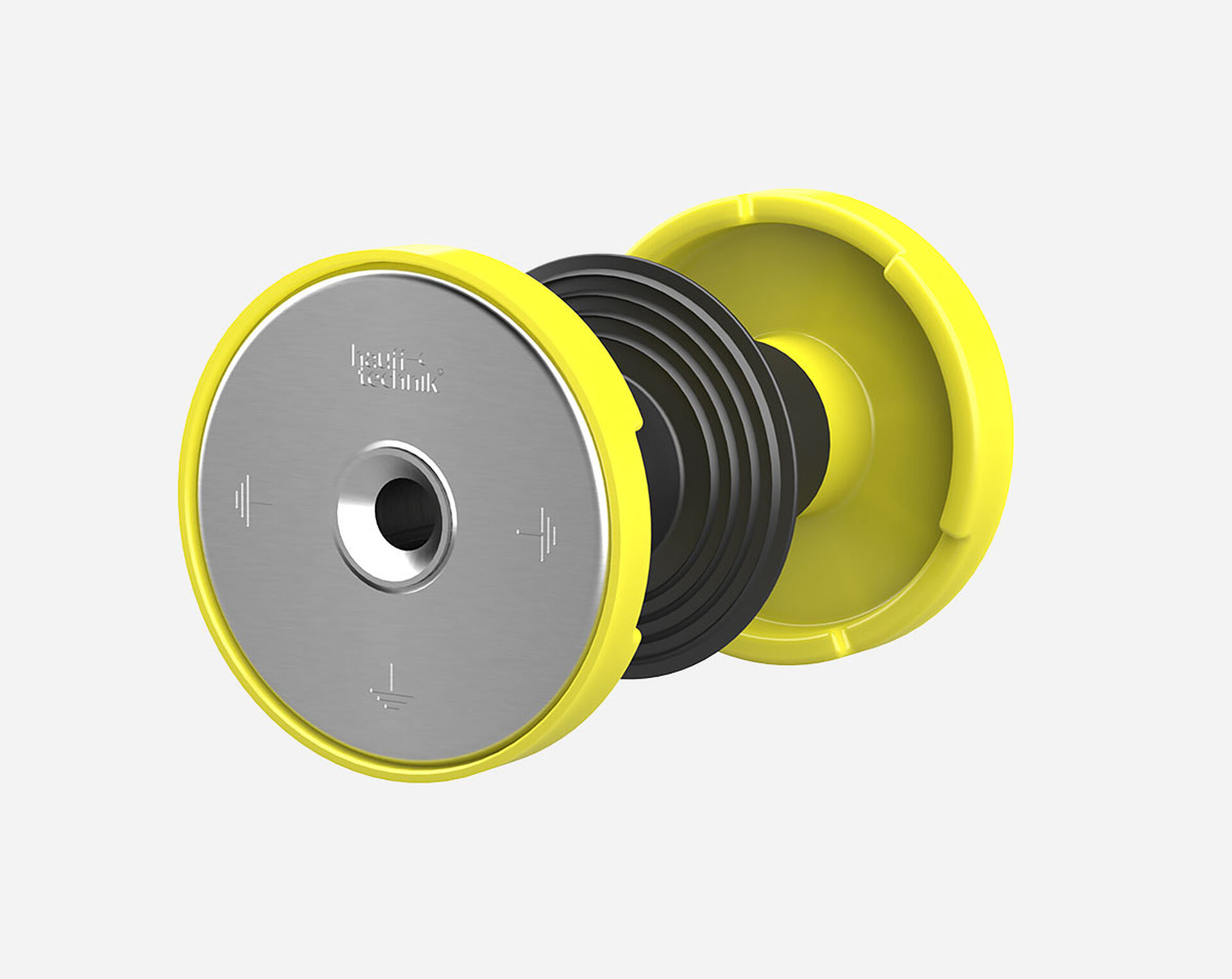

The system uses a pressure-tight closing cover, which comes pre-installed on all sealing packs, offering both water- and pressure-tight protection. The system cover allows for customized entries into the building, with pressure-tight empty conduits ready for future use.

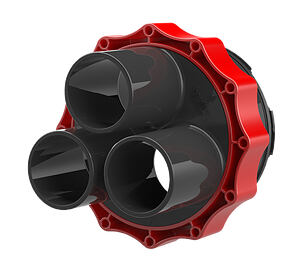

A 150 mm diameter entry accommodates three to six lines, depending on the size of the utility lines, whether it’s for electricity, fibre optics, or other utilities. Separate closing cover are provided for each line.

Additionally, a cable protection sleeve is used in the installation, encasing the utility line for safe entry into the building. The sleeve, made of a pressure-resistant spiral tube, can endure mechanical forces up to 2.5 bar. Its smooth interior ensures the gentle installation of lines, even at a later time, without pulling.

Diverse Solutions for Wall Entries from Hauff-Technik

When it comes to creating cable entries, Hauff-Technik offers a broad selection of options tailored to meet various requirements. Their portfolio includes complete cable entry systems, essential accessories, and customizable empty conduits that can be utilized as needed.

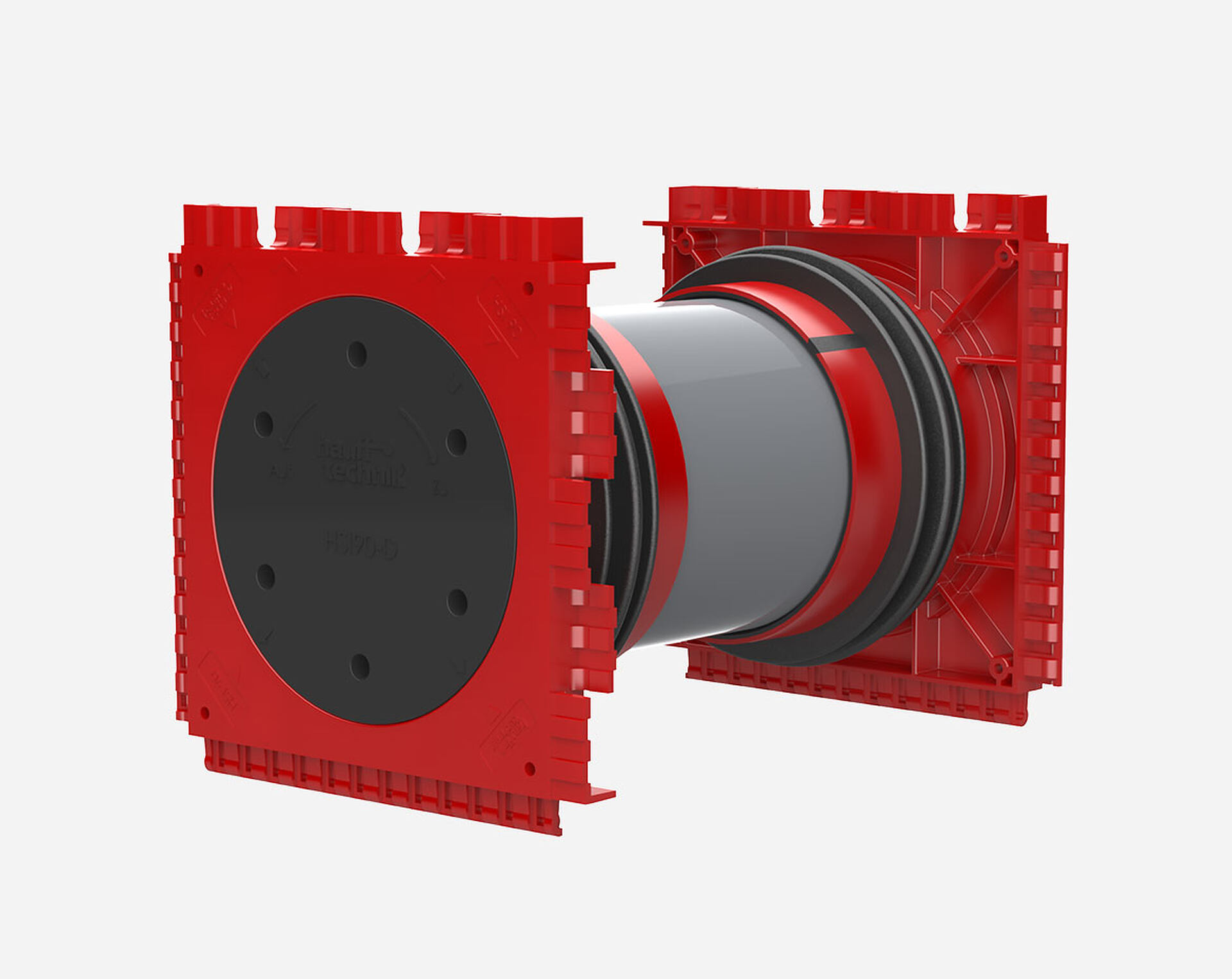

For wall penetrations, Hauff-Technik provides cable entries in diameters of 90 mm and 150 mm. These entries come standard with pressure-tight closing cover, available in angled configurations and with either single or double sealing packs. This flexibility allows you to design a complete system that addresses most cable entry tasks effectively.

Furthermore, Hauff-Technik offers inner pipes (Futterrohre) in different materials, suitable for embedding during the construction process. Options for retrofitting are also available, ideal for situations that require modifications, such as wall breakthroughs.

In cases where existing utility lines are already in place and cannot be separated, Hauff-Technik's renovation pipes come into play. These two-part renovation pipes can easily be installed around existing cables, creating fully gas- and watertight cable entries with the appropriate seals.

Available in lengths from 70 mm to 1,200 mm, Hauff-Technik's empty conduits come in a wide range of diameters, starting from 40 mm up to 900 mm, making them suitable for various installation requirements.

Cable Entries for Buildings – For Empty Conduits and Utility Lines

With a clear opening of 90 mm, cable entries represent a compact and secure option for connecting empty conduits in utility systems. These conduits enable various utility lines to be conveniently and safely routed into the building, making future cable installations simple and efficient. For this reason, Hauff-Technik’s solutions are ideal for future-proofing your installations.

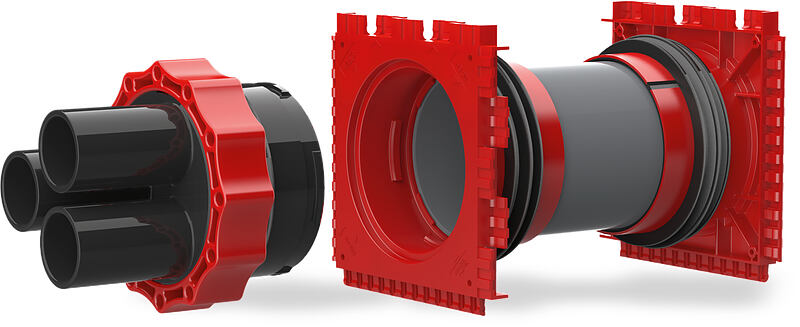

The Hauff-Technik system includes three essential components: the wall entry, system covers, and the cable entry system designed for the respective utility lines.

The Right Cable Entry for Every Construction Project

Construction conditions vary greatly from site to site, which is why tailored solutions are essential to safely and easily guide utility lines into buildings.

Hauff-Technik provides single and double sealing packs with a 90 mm diameter in multiple variations, including angled sealing packs. These enable utility lines to enter buildings from different angles, ensuring single- or double-sided gas- and watertight cable entries.

For retrofitted watertight cable entries, Hauff-Technik offers aluminum flanges. These flanges are mounted onto core drillings or enclosures, creating secure, gas- and watertight entries. They also support the installation of system covers, allowing empty conduits and utility lines to be routed through as needed.

Hauff-Technik also offers solutions for the safe, temporary provision of electrical connections during the construction phase. Their temporary power entries for transformer stations provide secure transitions, which can only be accessed with specialized tools, ensuring protection against unauthorized access.

Hauff-Technik's Cable Entry System for Empty Conduits and Utility Lines

Telecommunication lines and power cables enter buildings through wall penetrations, a crucial aspect of construction. To ensure a safe and secure entry, gas- and watertight cable entries are a necessity. Hauff-Technik’s cable entry systems provide exactly that.

Each entry comes with a pressure-tight closing cover, which allows utility lines to be routed into the building. During the early construction phase, empty conduits can be installed, or cables can be directly routed. Each cap can accommodate up to six cables, providing multiple connections in a compact, space-saving manner. The bayonet system prevents the cap from accidentally opening, and Hauff-Technik allows for millimeter-precise ring seal adjustments based on customer needs.

All connections—whether for empty conduits or active lines—are pressure-tight. Unused system caps can be sealed with blind plugs for future use, allowing for easy installation of new lines. The transition between the utility line and system cap is fully gas- and watertight, and both cold and heat shrink technologies can be applied for a perfect seal.

Heat shrink sleeves include adhesive to enhance the seal. A variety of stubs are available to fit utility lines with diameters between 8 and 72 mm. The connections are gas- and watertight up to 2.0 bar of pressure.

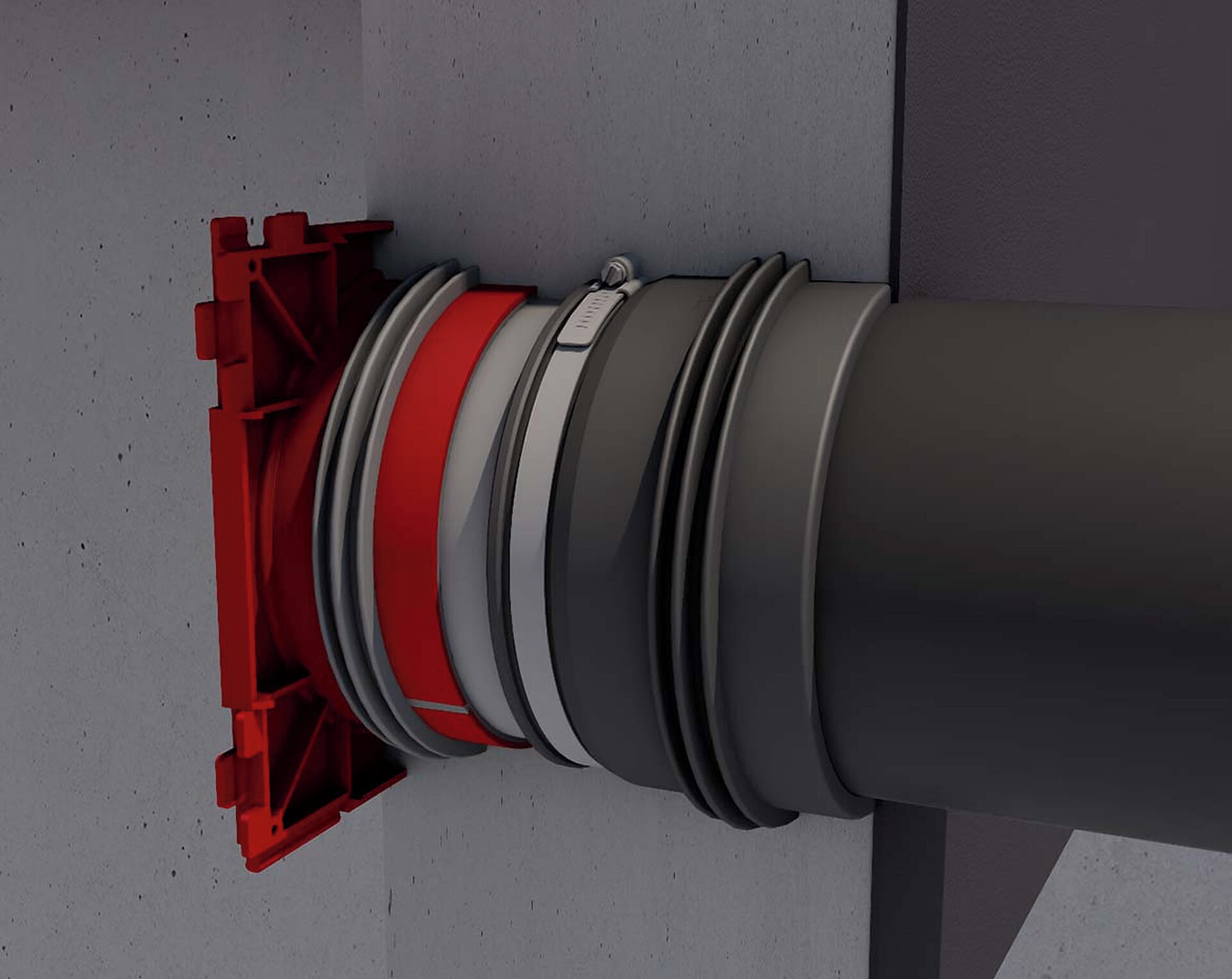

Hauff-Technik also provides external cable protection pipe solutions. Using a sleeve system, the connection between the system cap and the protection pipe is secure and long-lasting.

The sleeves have mechanical fixings with a bayonet system, while tension nuts ensure tightness. These systems are compatible with conduits of 90 and 110 mm in diameter, with gas- and watertight transitions up to 0.5 bar between the external protection pipe and the system cap.

Help us improve our website service.

Where would you place yourself?

Architect & designer

Wholesaler

Telecoms

Utility company

Installer

Construction company

Please choose your region

-

Belgium

Belgium

-

Česko

Česko

-

Danmark

Danmark

-

Deutschland

Deutschland

-

España

España

-

France

France

-

Global

Global

-

Hrvatska

Hrvatska

-

Italia

Italia

-

Luxembourg

Luxembourg

-

Magyarország

Magyarország

-

Nederland

Nederland

-

Österreich

Österreich

-

Polska

Polska

-

Schweiz

Schweiz

-

Slovenija

Slovenija

-

Slovensko

Slovensko

-

Sverige

Sverige

-

United Kingdom

United Kingdom

-

Global

Global

-

USA

USA

-

Global

Global

-

India

India

-

中国

中国

-

Global

Global

-

الإمارات العربية المتحدة

الإمارات العربية المتحدة